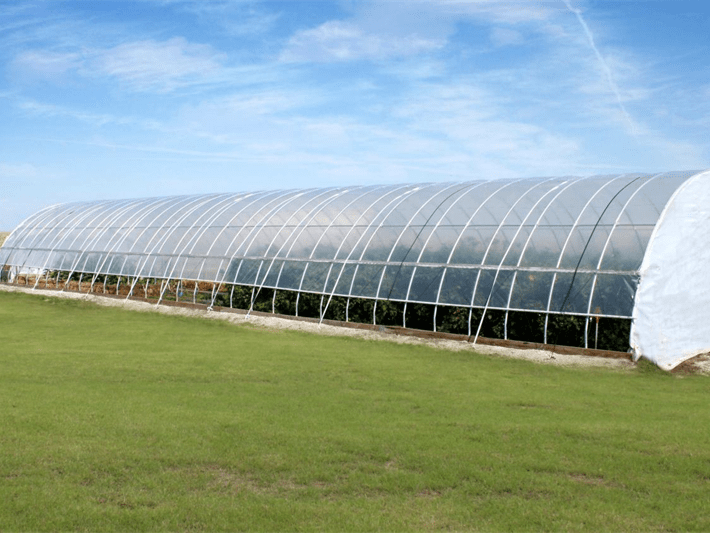

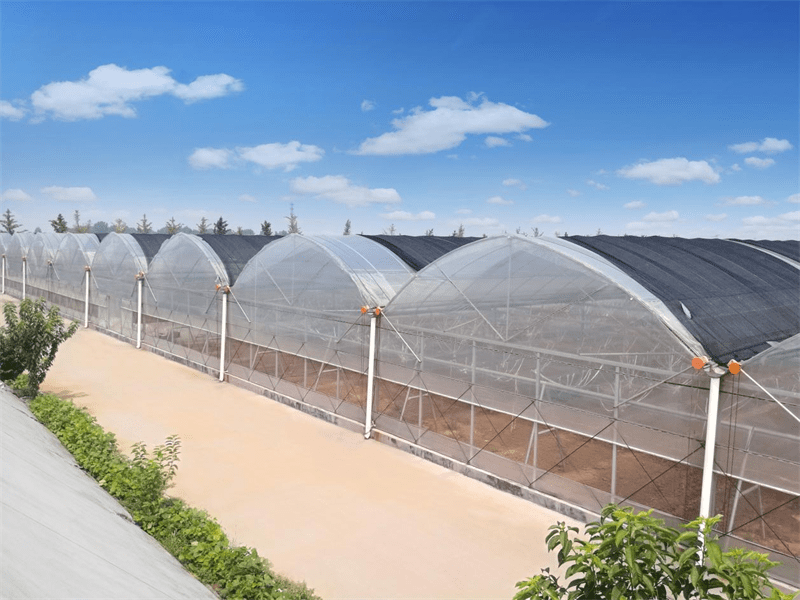

Multi-Span Film Greenhouse With Outer Sunshade System

description2

Characteristics of multi-span film greenhouses

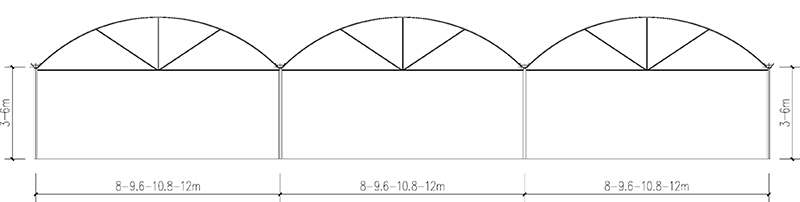

Parameters

| Type | Multi-span Film Greenhouse |

| Span Width | 8m/9.6m/10.8/12m |

| Bay width | 4m |

| Gutter height | 3-6m |

| Snow load | 0.15KN/㎡ |

| Wind load | 0.35KN/㎡ |

| Hanging load | 15KG/M2 |

| Max rainfall discharge | 140 mm/h |

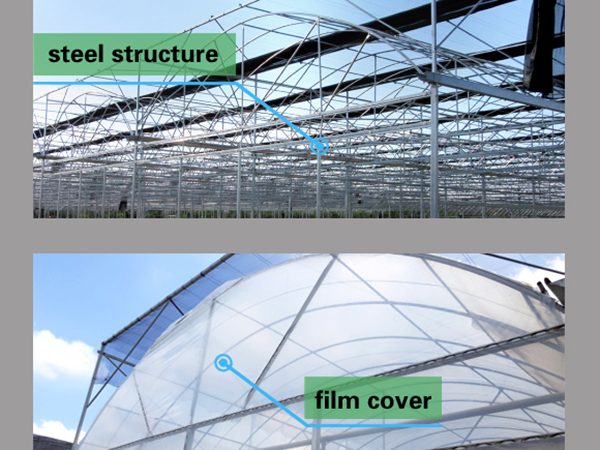

Greenhouse Cover&Structure

- 1. Steel Structure

- The steel structure material is made of high-quality carbon steel that meets national standards and is processed according to specific technical requirements for hot-galvanized steel production. The galvanized layer must meet certain standards, including thickness uniformity, absence of burrs, and a minimum thickness of 60um.

- 2. Cover material

- The cover material typically consists of PE film or PO film, with PE film produced using 3-layer technology and PO film using 5-layer technology. All films are coated with UV protection and are designed to be anti-drip and resistant to aging. The film thickness options include 120 microns, 150 microns, or 200 microns.

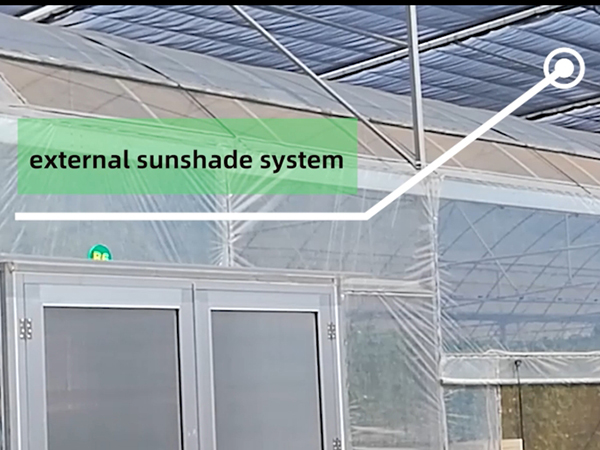

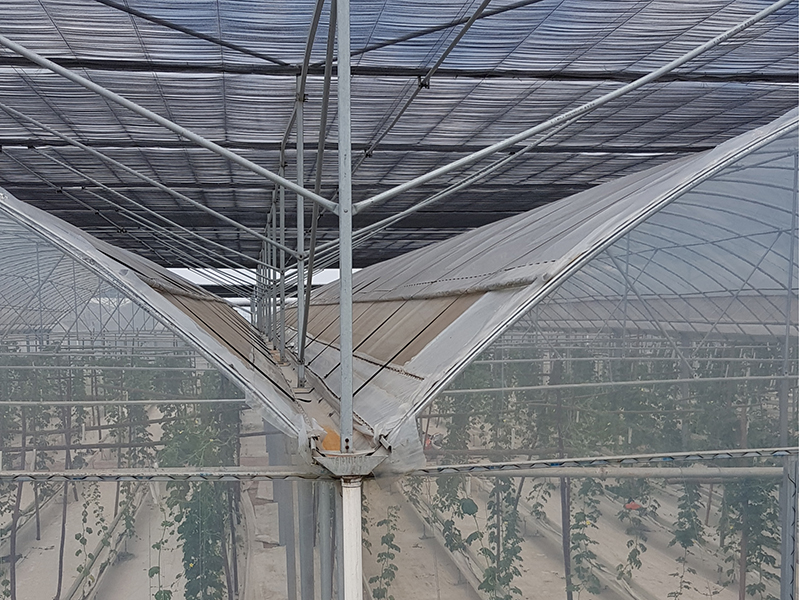

Outer Sunshade System

In the summer when indoor temperature rise to a certain value, it can reflect a part of the sun and diffuse sunshine into the greenhouse according to the different shading rate, achieving the purpose of cooling temperature. Close sunshade screen, at the same time the greenhouse temperature drop 4 ~ 6℃, reduce temperature in the greenhouse. By choosing different shading rate curtain, it can meet the sunshine demand of different crops.

Inner Sunshade&Warming System

The system involves the installation of an inner sunshade net within a greenhouse to regulate temperature. During the summer, it helps to lower the internal temperature, creating a more favorable environment for plant growth. In winter and at night, the net serves to retain heat and prevent it from dissipating. The system offers two distinct types: ventilation and thermal insulation, providing options for maintaining the desired climate within the greenhouse.

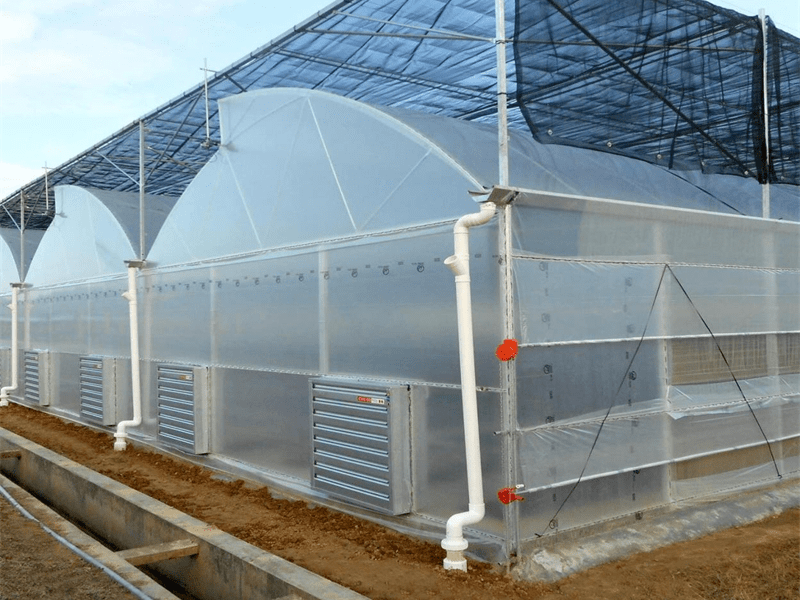

Cooling System

The cooling system operates by using the principle of water evaporation to lower temperature. It is equipped with high-quality cooling pads and powerful fans. The key component of the cooling system is the evaporative cooling pads, which are made of corrugated fiber paper and have a long working life due to corrosion-resistant properties from a special chemical composition added to the raw material. These special cooling pads ensure thorough wetting of the entire pad surface with water. As air passes through the pads, the exchange of water and air changes hot air into cool air while also humidifying and cooling the air.

Ventilation System

Greenhouse ventilation systems are divided into two types: natural ventilation and forced ventilation. Natural ventilation in film greenhouse uses roll film ventilation on the roof and sides. Insect-proof nets are installed at the ventilation openings, and the insect-proof nets are 60 mesh. Ventilation systems can be customized according to customer needs and growing conditions.

Light Compensating System

Greenhouse compensating light, also known asplant light, is essential for providing the necessary light for plants to grow and develop when natural sunlight is not available. This compensating light is needed to support plant growth and follows the natural law of plant growth, where plants use sunlight for photosynthesis. Currently, the majority of farmers use high pressure sodium lamps and LED lamps to provide this required light for their plants.

Irrigation System

We provide two kinds of irrigation systems: drip irrigation and spray irrigation. This allows you to pick the most suitable option for your greenhouse.

Nursery Bed System

The nursery bed consists of a fixed bed and a movable bed. The movable nursery bed is designed with specific specifications, including a seedbed standard height of 0.75m, which can be adjusted slightly. It has a standard width of 1.65m, which can be modified to match the greenhouse's width, and the length can be customized according to the user's requirements. The movable bed grid measures 130mm x 30mm (length x width), and it is made of hot-dip galvanized material, providing high corrosion resistance, excellent load-bearing capacity, and a long service life. The fixed bed, on the other hand, has a length of 16m, a width of 1.4m, and a height of 0.75m.

CO2 Control System

The primary objective is to maintain continuous monitoring of the CO2 concentration within the greenhouse to ensure it falls within the suitable range for crop growth. This is primarily achieved using a CO2 detector and a CO2 generator. A CO2 sensor is utilized to detect the concentration of CO2, enabling real-time monitoring and adjustment of environmental parameters within the greenhouse to create an optimal growth environment for plants.