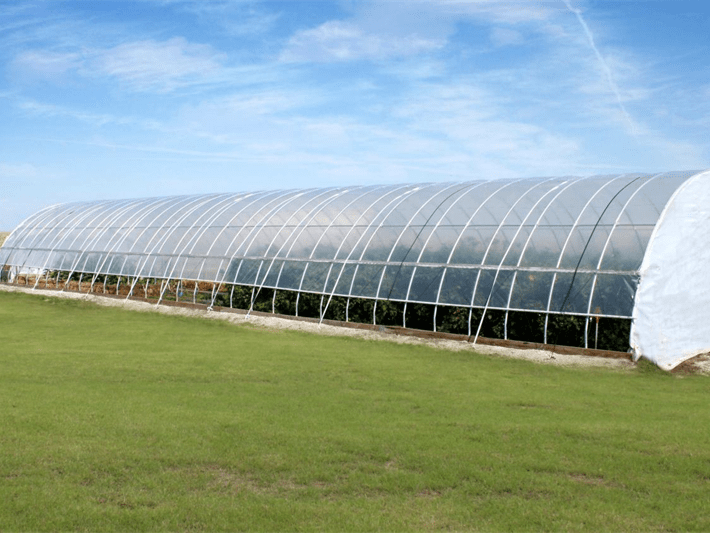

Venlo Polycarbonate Greenhouse With Hydroponic System

description2

Polycarbonate sheet has the following characteristics

Parameters

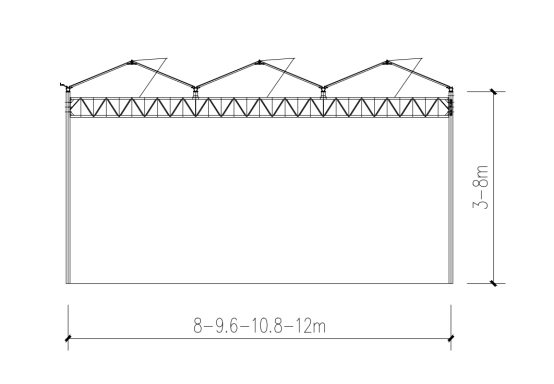

| Type | Polycarbonate Greenhouse |

| Span Width | 8m/9.6m/10.8m/12m |

| Bay width | 4m /8m |

| Gutter height | 3-8m |

| Snow load | 0.5KN/M2 |

| Wind load | 0.6KN/M2 |

| Hanging load | 15KG/M2 |

| Max rainfall discharge | 140 mm/h |

Greenhouse Cover&Structure

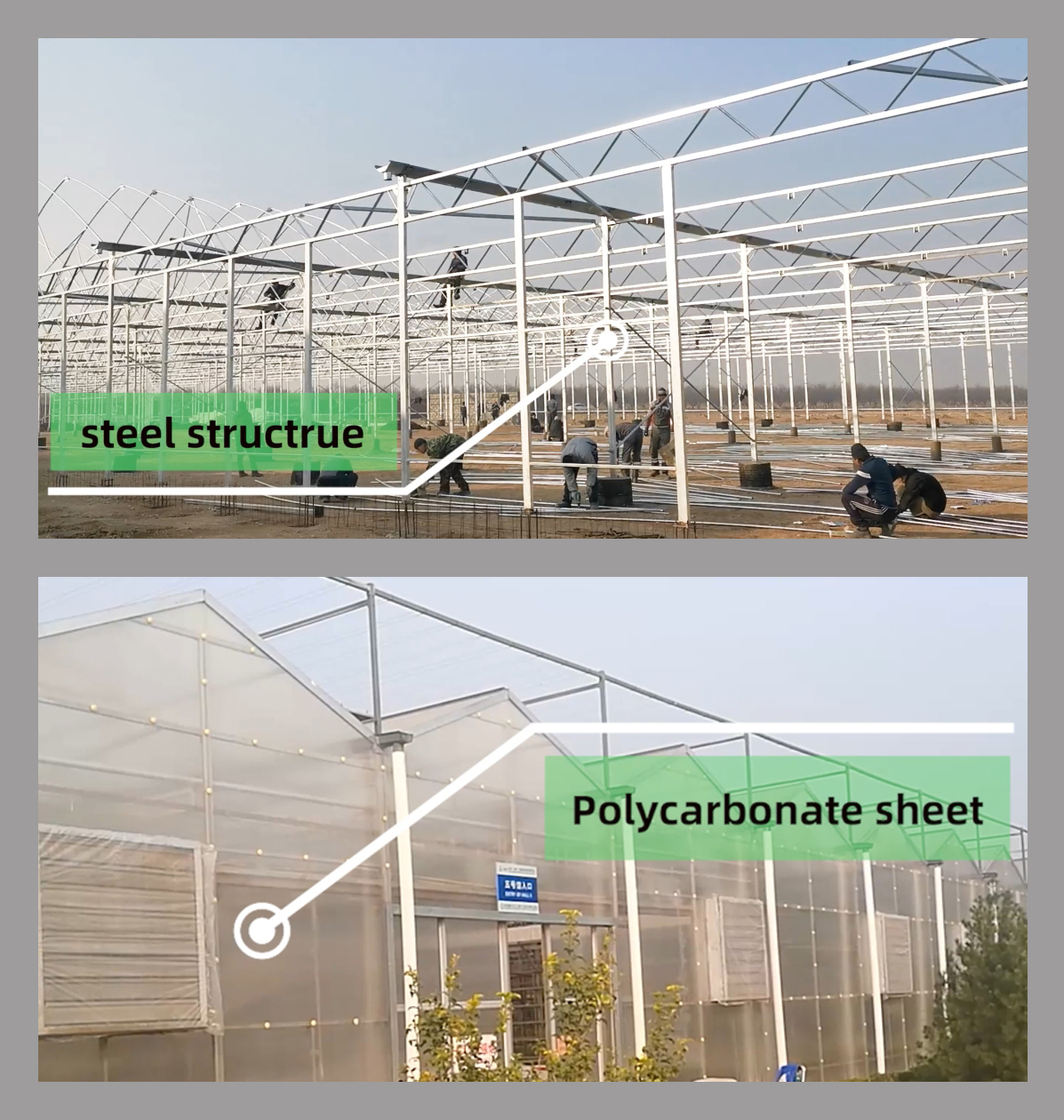

- 1. Steel Structure

- Steel structure material is high quality carbon steel which is accordance with national standard. Steel parts and fasteners are processed according to “GB/T1912-2002 Technical Requirements and Test Methods of Hot-galvanized Layer for Metal Coating Steel Production”. Inside and outside hot galvanized steel should meet the national standard (GB/T3091-93) requirements of quality products. Galvanized layer should have thickness uniformity, no burr, and the galvanized layer thickness is not less than 60um.

- 2. Cover material

- The polycarbonate sheet is typically available in 6mm, 8mm, and 10mm thicknesses, and comes with a 10-year warranty. It is equipped with UV-coating on the outer surface and boasts anti-drip and anti-aging properties.

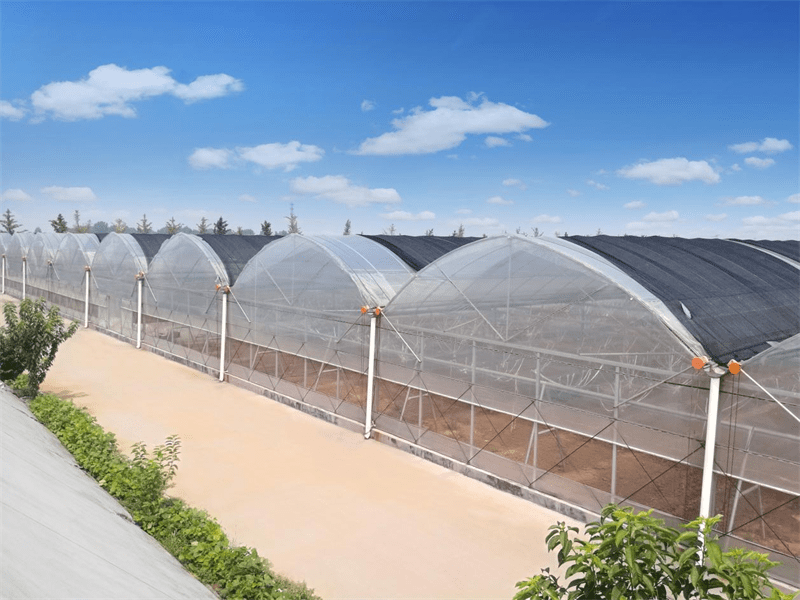

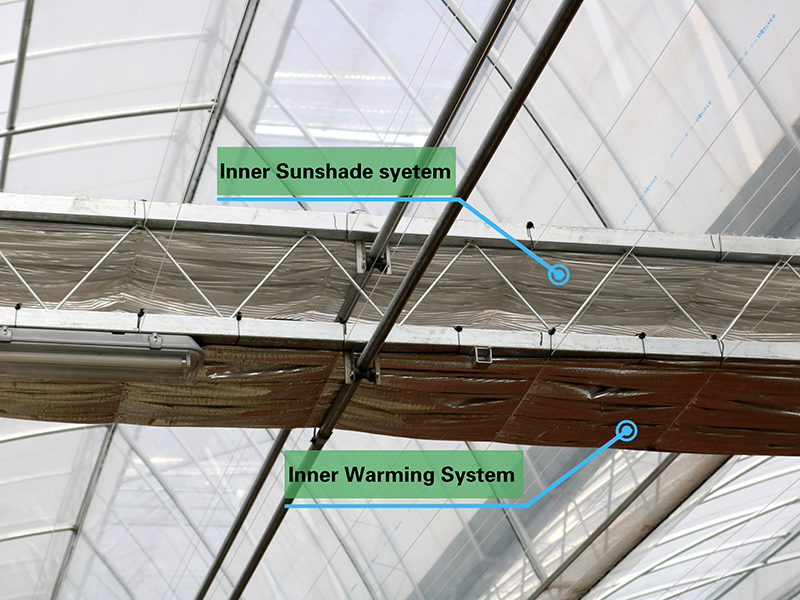

Inner Sunshade&Warming System

Sunshade net is being installed inside the greenhouse to regulate temperature. The net helps to lower the internal temperature during the hot summer months. Moreover, it acts as insulation to prevent heat loss during winter and nighttime. The system offers two options: a ventilation type and a thermal insulation type, catering to different needs and climates.

The internal thermal insulation curtain system is primarily utilized in colder climates with temperatures below 5°C. It functions to minimize heat loss through infrared radiation on chilly nights, thus cutting down on surface heat loss and reducing the energy required for heating. Ultimately, this can lead to decreased operating expenses for greenhouse facilities.

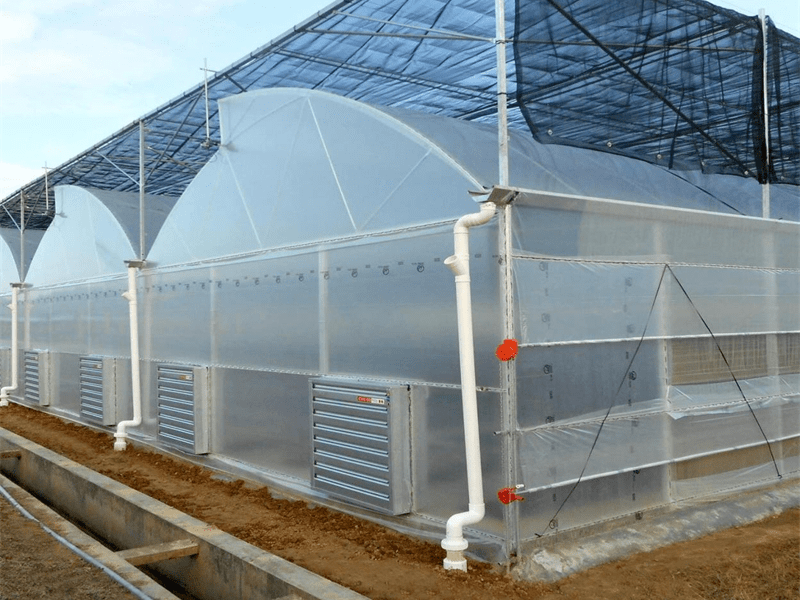

Cooling System

The cooling system has the ability to reduce temperature through the evaporation of water. It includes high-quality cooling pads and powerful fans. The core of the cooling system consists of cooling pads made of corrugated fiber paper, which is corrosion-resistant and has a long working life due to the addition of a special chemical composition to the raw material. These special cooling pads ensure that the entire surface is wet with water. As air passes through the pads, the exchange of water and air transforms hot air into cool air while also humidifying the air.

Ventilation System

The ventilation systems in greenhouses are categorized into natural ventilation and forced ventilation. In film greenhouses, natural ventilation employs roll membrane ventilation on both the roof and sides. Additionally, the sawtooth greenhouse primarily utilizes roll film ventilation for roof ventilation. To prevent insects from entering through the ventilation openings, 60 mesh insect-proof nets are installed. Furthermore, ventilation systems can be tailored to meet the specific requirements of customers and the growing conditions of the plants.

Heating System

The heating system can be classified into two types: one type utilizes a boiler to generate heat, while the other type relies on electricity for heating purposes. When using a boiler, a variety of fuel options such as coal, oil, gas, and biofuels are available. Boilers require the installation of pipelines and a water warming blower to distribute heat. On the other hand, if electricity is used, an electric warm air blower is needed for heating.

Light Compensating System

Greenhouse compensating light, also known as plant light, provides the necessary light for plant growth and development in the absence of natural sunlight. This compensates for the sunlight that plants would normally receive. Currently, many farmers use high pressure sodium lamps and LED lamps to provide this compensating light for their plants.

Irrigation System

The greenhouse watering system includes a water purification unit, water storage tank, irrigation setup, and a combined water and fertilizer system. We provide a choice between drip irrigation and spray irrigation, so you can choose the most appropriate method for your greenhouse needs.

Nursery Bed System

The nursery bed includes both fixed and movable beds. The movable nursery bed has specific dimensions: a standard height of 0.75m, which can be adjusted slightly, a standard width of 1.65m that can be altered to match the greenhouse width, and a customizable length based on user requirements. The grid for the movable bed is 130mm x 30mm in dimensions, made of hot-dip galvanized material, with high corrosion resistance, excellent load-bearing capacity, and a long service life. The fixed bed, on the other hand, has a length of 16m, a width of 1.4m, and a height of 0.75m.

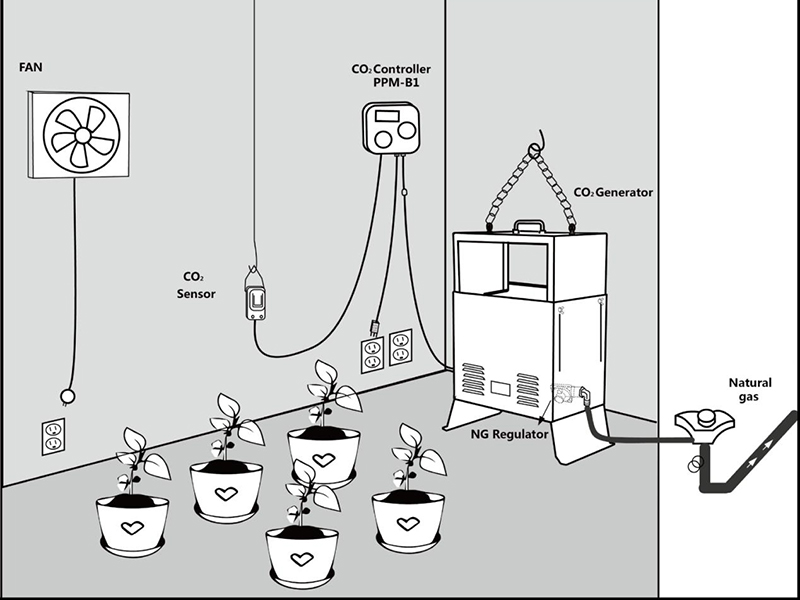

CO2 Control System

The primary goal is to monitor CO2 levels in the greenhouse in real time, ensuring they remain within the optimal range for crop growth. This is achieved through the use of a CO2 detector and a CO2 generator. The CO2 sensor serves the purpose of detecting and measuring the concentration of CO2. By continuously monitoring the greenhouse's environmental conditions, it can make necessary adjustments based on the data gathered to guarantee an optimal growth environment for plants.

Control System

The greenhouse control system typically consists of a control cabinet, sensors, and circuits. These components work together to enable semi-automatic control of the greenhouse environment. Additionally, by integrating networking technology, it is possible to use a computer to intelligently manage and control various aspects of the greenhouse systems. This allows for more precise and efficient control of environmental conditions within the greenhouse.