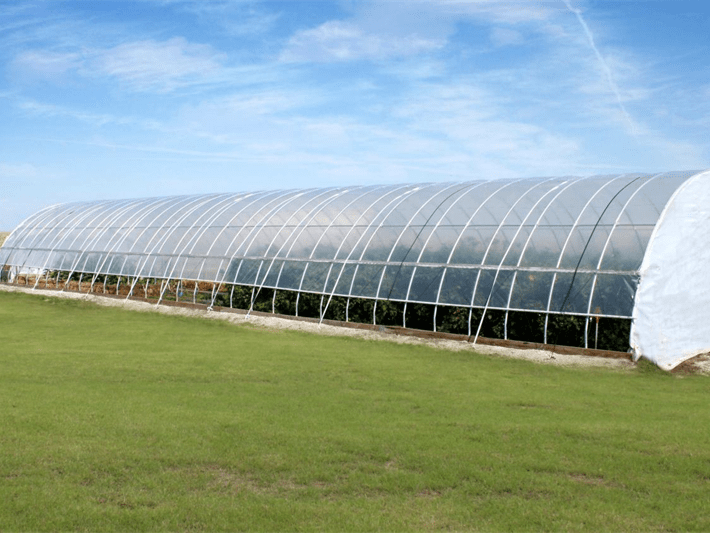

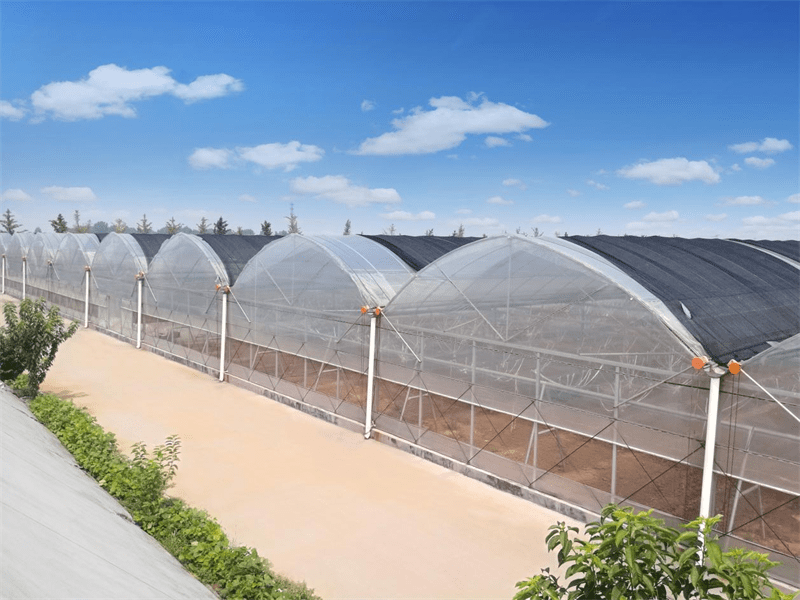

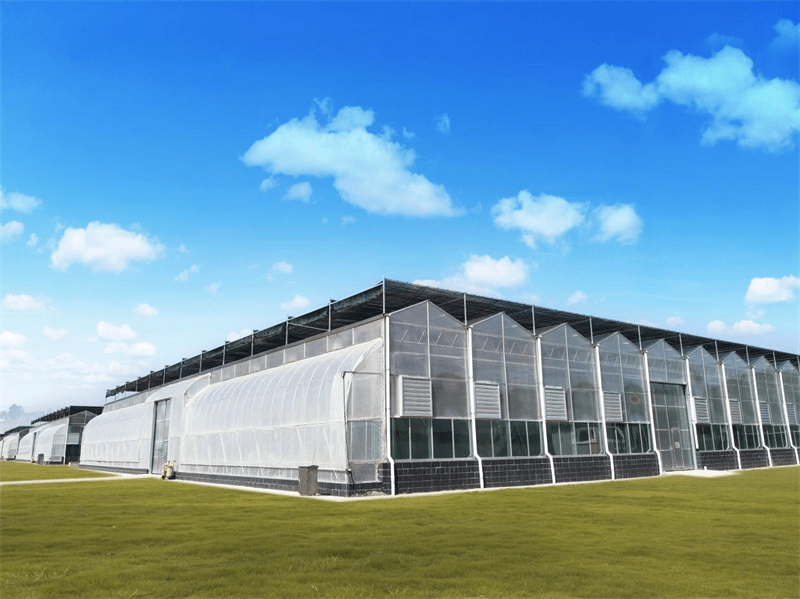

Multi-Span Agricultural Polycarbonate Greenhouse With Outer Sunshade System

description2

Polycarbonate sheet has the following characteristics

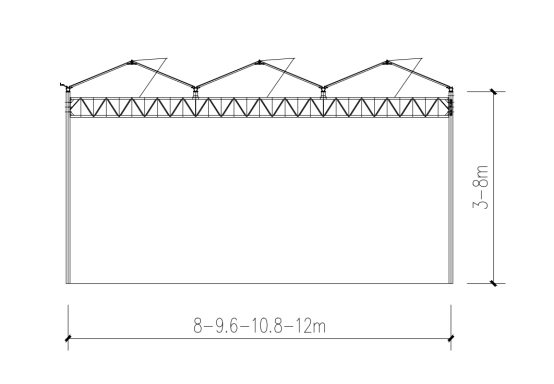

Parameters

| Type | Polycarbonate Greenhouse |

| Span Width | 8m/9.6m/10.8m/12m |

| Bay width | 4m / 8m |

| Gutter hight | 3-8m |

| Snow load | 0.5KN/M2 |

| Wind load | 0.6KN/M2 |

| Hanging load | 15KG/M2 |

| Max rainfall discharge | 140 mm/h |

Greenhouse Cover&Structure

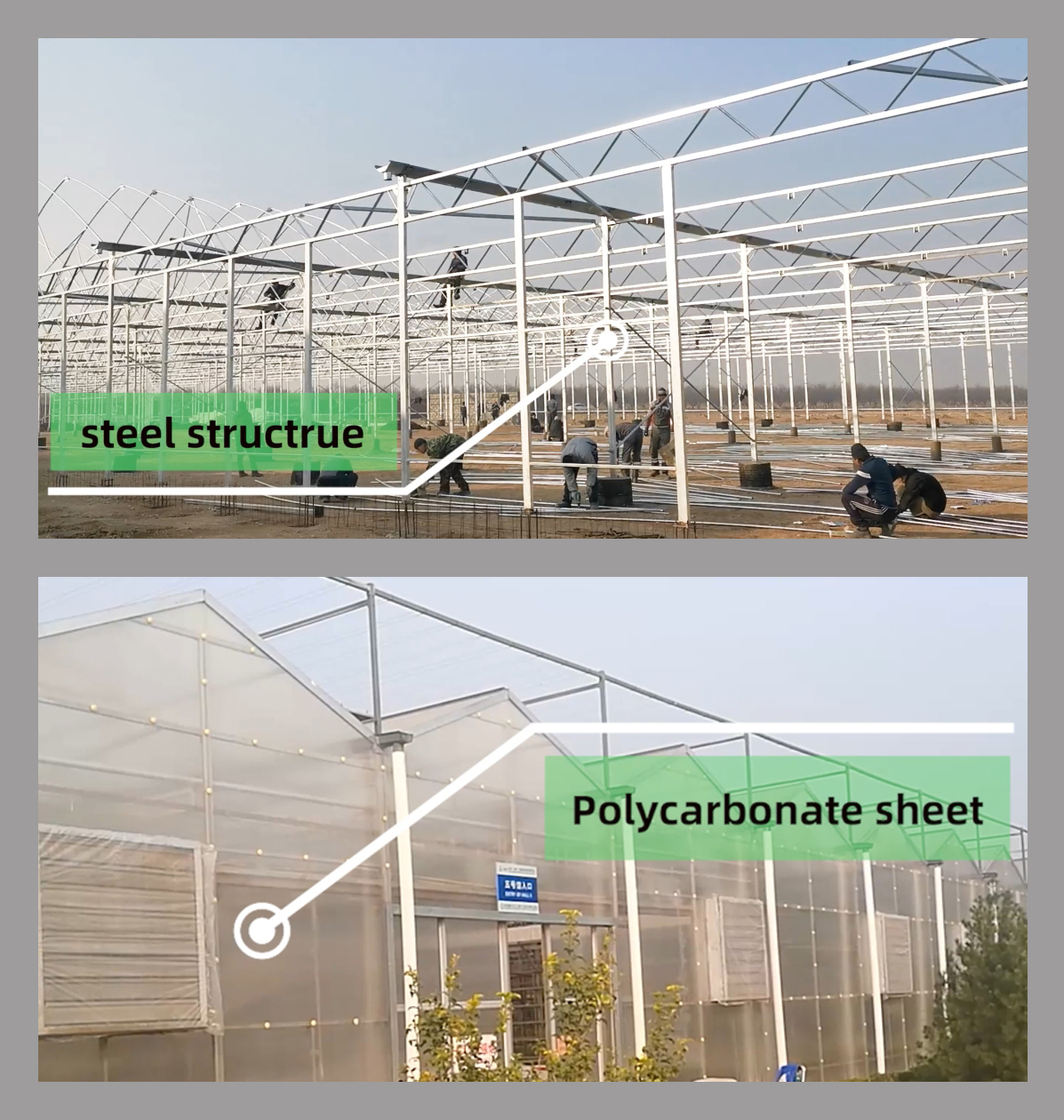

- 1. Steel Structure

- Steel structure material is high quality carbon steel which is accordance with national standard. Steel parts and fasteners are processed according to “GB/T1912-2002 Technical Requirements and Test Methods of Hot-galvanized Layer for Metal Coating Steel Production”. Inside and outside hot galvanized steel should meet the national standard (GB/T3091-93) requirements of quality products. Galvanized layer should have thickness uniformity, no burr, and the galvanized layer thickness is not less than 60um.

- 2. Cover material

- Name: Polycarbonate

- The polycarbonate sheet thickness is usually 6mm, 8mm, and 10mm. The warranty period is 10 years. On the external side, there is UV-coating layers and it also has characteristic of anti-drip and anti-aging.

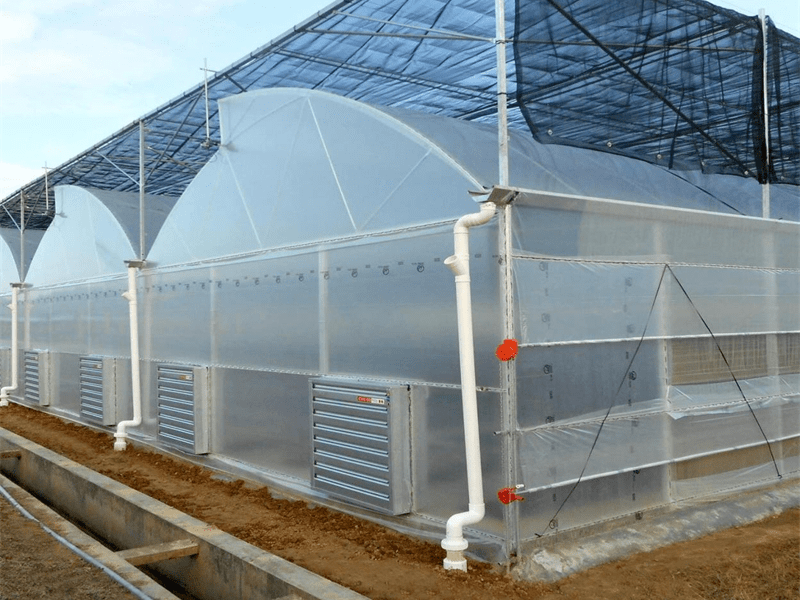

Outer Sunshade System

In the summer when indoor temperature rise to a certain value, it can reflect a part of the sun and diffuse sunshine into the greenhouse according to the different shading rate, achieving the purpose of cooling temperature. Close sunshade screen, at the same time the greenhouse temperature drop 4 ~ 6℃, reduce temperature in the greenhouse. By choosing different shading rate curtain, it can meet the sunshine demand of different crops.

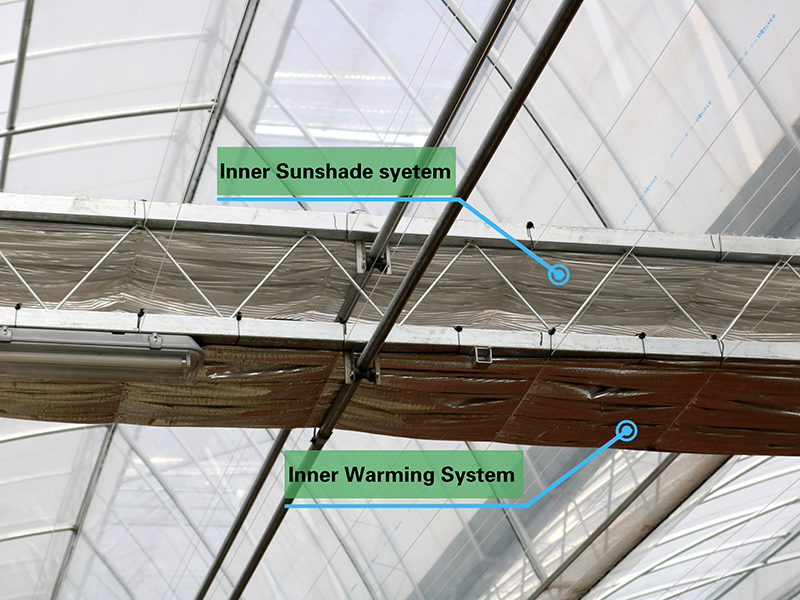

Inner Sunshade&Warming System

This system is installing inner sunshade net in the greenhouse.In summer, it can reduce the inner temperature, and in winter and in night, it can prevent the heat running off. It has two types, ventilation type and thermal insulation type.

The internal thermal insulation curtain system is primarily utilized in colder climates with temperatures below 5°C. It functions to minimize heat loss through infrared radiation on chilly nights, thus cutting down on surface heat loss and reducing the energy required for heating. Ultimately, this can lead to decreased operating expenses for greenhouse facilities.

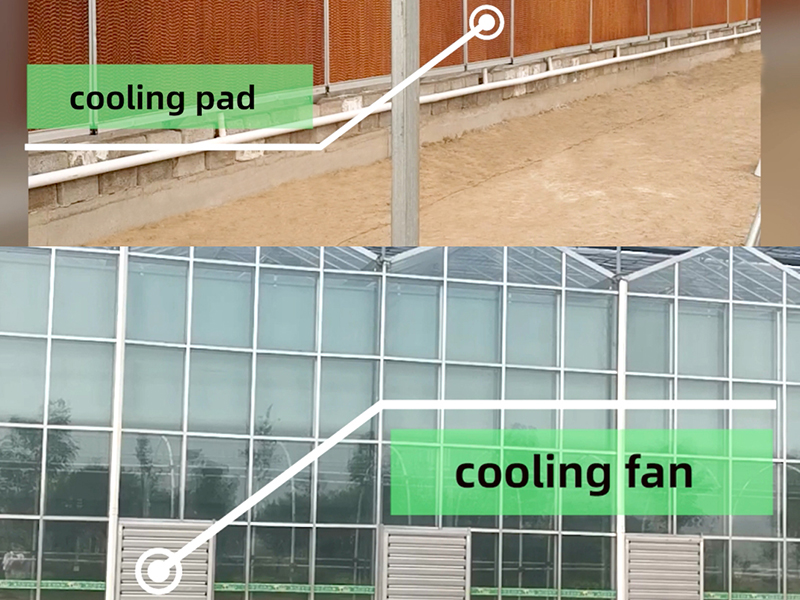

Cooling System

Cooling system can decrease the temperature according to the principle of evaporation of water for cooling. System has high-quality cooling pads and the fans with big wind.The core of cooling system is the cooling pads, which can evaporate water, is made of corrugated fiber paper.it is corrosion resistant and has long working life, because the raw material is added to a special chemical composition. The special cooling pads can ensure the water wets whole wall of cooling pads. When the air goes through the pads, the exchange of water and air on the surface of pads can change the hot air into cool air, then it can humidify and cool the air.

Ventilation System

Greenhouse ventilation system is divided into two kinds, natural and forced ventilation. Polycarbonate greenhouse natural ventilation is opening staggered windows on the roof. Forced ventilation is achieved through installing blowers. In general, we install the cooling system of fans and cooling pad. Ventilation systems can be customized according to customer needs and planting conditions.

Heating System

Heating system has two types, one type is using the boiler to provide heat, and another uses of electric. Boiler fuel can choose coal, oil, gas and bio fuels. Boilers need laying of pipelines and water warming blower to heat. If use electricity, you need electric warm air blower to heat.

Light Compensating System

Greenhouse compensating light, also called plants light, is a required light of supplying light to the plants for growing and developing, instead of sunlight according to the natural law of plant growth and the principle of plants using sunlight for photosynthesis. At this moment most of farmers use high pressure sodium lamp and LED lamp.

Irrigation System

The greenhouse watering system includes a water purification unit, water storage tank, irrigation setup, and a combined water and fertilizer system. We provide a choice between drip irrigation and spray irrigation, so you can choose the most appropriate method for your greenhouse needs.

Nursery Bed System

Nursery bed has Fixed bed and movable bed. Movable nursery bed specifications: seedbed standard height 0.75m, can be adjustable a little. Standard width 1.65m, can be changed according to the width of the greenhouse, and length can be customized according to the user requirements; movable bed grid 130 mm x 30 mm (length x width), hot dip galvanized material, high corrosion resistance, good load-bearing capacity, long service life. Specifications for the fixed bed: length 16m, 1.4m wide, height 0.75m.

CO2 Control System

The main purpose is to achieve real-time monitoring of the CO2 concentration in the greenhouse, so that the CO2 in the greenhouse is always within the range of crops suitable for crop growth.Mainly including CO2 detector and CO2 generator. The CO2 sensor is a sensor used to detect CO2 concentration. It can monitor the environmental parameters in the greenhouse in real time and make adjustments based on the monitoring results to ensure a suitable growth environment for plants.

Control System

Greenhouse control system is generally composed of control cabinet, sensors and circuits, which can be realized semi automatic control. You can also use the computer to intelligently control the greenhouse systems through installing networking.